The load cycles will be very low for this application as it is not a rotating assembly like a motor/pump. The splined length of the slack adjuster is 1.00". The slack adjuster can apply ~2,300 lb*ft of torque max to the shaft. I don't believe the application is severe.

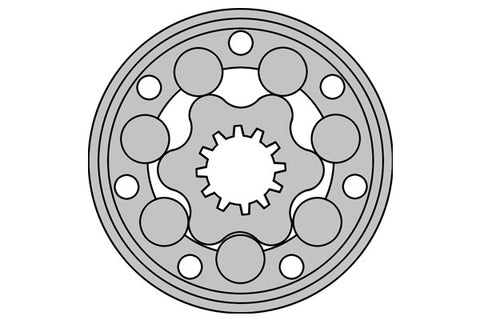

The method and amount of "breaking" sharp corners and edges also depend upon the conditions and requirements of each application." SAE J499 makes reference to the shaft dimensions, but only states the following: "The shaft dimensions depend upon the shape and material of the parts, their heat treatment, and methods of machining to give the required fit. I can not find any references to what the external dimensions of the shaft splines should be. I have a copy of the 28th edition Machinery's Handbook, but can only find dimensional information regarding the internal splines (specifically for broached holes). The slack adjuster mates to the shaft by a 1.5" - 10C SAE spline. The slack adjuster acts as a lever arm to rotate a shaft which engages the brake pad to the rail wheel. I'm designing an air brake system for a railroad application which will use automatic slack adjusters which are typically found on over the road trucks/trailers.

After several years of referencing this website, I've decided to post a question I haven't been able to find an answer to.

0 kommentar(er)

0 kommentar(er)